Stranding

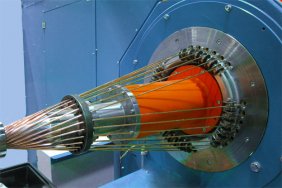

Cables for fixed installation in wire channels or long walls or long sealings of rooms need to be bendable. Cores for moveable electric devices and units need to be flexible. The required processability is achieved by using stranded conductors inside the cable which are produced on stranding machines.

Stranding is the process where a particular number of stranding elements are joined together while winding them round a common axis.

Stranding is a result of rotating and forward movement. The rotation creates winding of the stranding elements around an axis or a center element. The forward movement is made using a capstan.

The most common and simplest stranding system is the 6-wire system. This system has a center element and 6 wires are helically laid around this center element. All additional layers on top of this one have 6 wires more than the layer before. For example 1+6+12+18+24 etc.

When using the 6-wire system all wires in all layers have exactly the same diameter. Such a design is called concentric design.

Lay-length

The lay-length is the measurement parallel along the axis that every individual stranding element needs for one complete winding around the axis.

Stranding direction

The stranding direction can be indicated when looking on the rope in the roll axis. When looking on a right-stranded rope the stranding elements are going from front left to down right. For this direction the character “Z” is indicated. The character “S“ is symbolic for left stranding. The assignment of “S” or “Z” is related to the center of the character which either goes right to left or left to right.

The cross lay stranding has an opposite direction of each layer to the one before.

When designing the cable with mono lay all layers have the same stranding direction.

Compacting

Round conductors

When compacting a round conductor this is usually made using the stranding nipple and/or compacting rollers. Both ways of compacting are reducing the cross section of the individual wires until the strand has the requested diameter. The geometric shape of the cross section regarding the single wire is unevenly changed.

Sector conductors

To reduce the cross section of stranded conductors, especially for energy cable, sector shaped conductors are replacing round conductors. Multi wire sector conductors are always compacted.

Depending on cable design there are 60°, 90°, 100° and 120° sectors. The sum of the angle of the individual conductors has to be 360°.

Compacting and production of sector shaped conductors is usually made using compacting rollers.

Type of machines

There is a wide range of machinery and accessories for stranding. For the best choice of the right stranding line, cable type (data cable, energy cable, special cable) material characteristics and quality requirements for this cable as well as available space and manufacturing program are the factors to select the right equipment.

Generally the idea is to have flexible machinery. Flexible means that the stranding line can handle as many as possible of the stranding duties to be produced.

Our delivery program includes the following stranding lines:

- Tubular and skip stranding lines for production of steel strands, copper strands and aluminium strands.

- Rigid stranding lines without backtwist for the production of copper strands and aluminium strands and ropes. This machine can be delivered with row by row loading or individual loading.

- Planetary stranding machines with backtwist for the production of steel ropes or for armouring of cables. The machines are equipped with backtwist and can operate with 0% and 100% or variable backtwist.

- Closing machines such as:

- Drum twister

- Bow cabler

- Planetary machines

STOLBERGER Solutions

Products are loading…

![tubular strander HST 560]()

New: Tubular stranding line

1 + 6 bobbins ø 560 mm (22”), 1000 or 700 rpm

Ref.-No.: 10-5443

Model: HST 560

read more

![Tubular stranding line]()

New: Tubular stranding line

1 + 6 bobbins ø 630 mm (24,8”), 900 or 600 rpm

Ref.-No.: 10-5444

Model: HST 630

read more

![Tubular stranding line]()

New: Tubular stranding line

1 + 6 or 1 + 9 bobbins ø 710 mm (27,9”), 800 rpm / 600 rpm

Ref.-No.: 10-5444

Model: HST 710

read more

![Bow twister machine]()

New: Bow twister machine

1 + 6 bobbins ø 560 mm (22”), 1800 rpm

Ref.-No.: 12-7235

Model: QSS

read more

![Bow twister machine]()

New: Bow twister machine

1 + 6 bobbins ø 630 mm (24,8”), 1400 rpm

Ref.-No.: 12-6038

Model: QSS

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 900 mm (35,4”), 500 rpm

Ref.-No.: 12-5932

Model: QRL

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 1250 mm (49,2”), 500 rpm

Ref.-No.: 12-5650

Model: QRL

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 1600 mm (63”), 400 rpm

Ref.-No.: 12-5651

Model: QRL

read more

![Rotating pay off for drum twister lines]()

New: Rotating pay off for drum twister lines

reel flange ø 1600 – 3000 mm (63 – 118,1”), separate DC-drive

Ref.-No.: 16-7003

Model: RPO

read more

![Rigid stranding line FLR 800]()

New: Fast loading rigid stranding line

12 + 18 + 24 bobbins ø 800 mm (31,5”) with semi-automatic loading system

Ref.-No.: 14-6795

Model: FLR 800

read more

![Planetary closing machine]()

New: Planetary closing machine

12 - 20 drums ø 2250, 2600 or 3000 mm (88, 12 or 118"), max. weight of each drum 30 tons

Ref.-No.: 15-7200

Model: QPC

read more

![Tubular stranding line]()

New: Tubular stranding line

tubular stranding line for the manufacturing of steel ropes, max. 1200 rpm., 36 bobbins ø 355 mm...

Ref.-No.: 10-7396

Model: 36 HST 355

read more

Products are loading…

![tubular strander HST 560]()

New: Tubular stranding line

1 + 6 bobbins ø 560 mm (22”), 1000 or 700 rpm

Ref.-No.: 10-5443

Model: HST 560

read more

![Tubular stranding line]()

New: Tubular stranding line

1 + 6 bobbins ø 630 mm (24,8”), 900 or 600 rpm

Ref.-No.: 10-5444

Model: HST 630

read more

![Bow twister machine]()

New: Bow twister machine

1 + 6 bobbins ø 560 mm (22”), 1800 rpm

Ref.-No.: 12-7235

Model: QSS

read more

![Bow twister machine]()

New: Bow twister machine

1 + 6 bobbins ø 630 mm (24,8”), 1400 rpm

Ref.-No.: 12-6038

Model: QSS

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 900 mm (35,4”), 500 rpm

Ref.-No.: 12-5932

Model: QRL

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 1250 mm (49,2”), 500 rpm

Ref.-No.: 12-5650

Model: QRL

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 1600 mm (63”), 400 rpm

Ref.-No.: 12-5651

Model: QRL

read more

![Planetary closing machine]()

New: Planetary closing machine

12 - 20 drums ø 2250, 2600 or 3000 mm (88, 12 or 118"), max. weight of each drum 30 tons

Ref.-No.: 15-7200

Model: QPC

read more

![Planetary armouring line]()

New: Planetary armouring line

up to 120 bobbins ø 630 mm (25"), product ø 300 mm (11,8")

Ref.-No.: 15-7201

Model: QPS

read more

Products are loading…

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 900 mm (35,4”), 500 rpm

Ref.-No.: 12-5932

Model: QRL

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 1250 mm (49,2”), 500 rpm

Ref.-No.: 12-5650

Model: QRL

read more

![Bow twister machine]()

New: Bow twister machine

1 + 3 bobbins ø 1600 mm (63”), 400 rpm

Ref.-No.: 12-5651

Model: QRL

read more

![Planetary closing machine]()

New: Planetary closing machine

12 - 20 drums ø 2250, 2600 or 3000 mm (88, 12 or 118"), max. weight of each drum 30 tons

Ref.-No.: 15-7200

Model: QPC

read more

Products are loading…

![43-wire transposing line]()

New: 43-wire transposing line

bobbin ø 500 mm (19,7”), complete line with taping heads 8 x 500 mm (19,7”), caterpillar...

Ref.-No.: 15-6809

Model: 43 QTM 500

read more

![85-wire transposing line]()

New: 85-wire transposing line

bobbin ø 550 mm (21,7”), complete line with taping heads 8 x 500 mm (19,7”), caterpillar...

Ref.-No.: 15-7329

Model: 85 QTM 550

read more

![67-wire transposing line]()

New: 67-wire transposing line

bobbin ø 550 mm (21,7”), complete line with taping heads 8 x 500 mm (19,7”), caterpillar...

Ref.-No.: 15-7266

Model: 67 QTM 550

read more

Products are loading…

![tubular strander HST 560]()

New: Tubular stranding line

1 + 6 bobbins ø 560 mm (22”), 1000 or 700 rpm

Ref.-No.: 10-5443

Model: HST 560

read more

![Tubular stranding line]()

New: Tubular stranding line

1 + 6 bobbins ø 630 mm (24,8”), 900 or 600 rpm

Ref.-No.: 10-5444

Model: HST 630

read more

![Planetary armouring line]()

New: Planetary armouring line

up to 120 bobbins ø 630 mm (25"), product ø 300 mm (11,8")

Ref.-No.: 15-7201

Model: QPS

read more